Pod refers to the payload container device suspended outside the moving carrier (such as aircraft and ship). According to the different functions of built-in equipment, it can be divided into navigation pods, aiming pods, infrared measurement pods, and electronic interference pods. And electronic intelligence pods, etc. The unmanned aerial vehicle system generally mounts optoelectronic pods, and also includes related consoles (stations), mission loads and control links, among which spherical optoelectronic pods (hereinafter referred to as pods) are UAV optoelectronic loads. It has various types, complex parameters and many manufacturers, which causes some troubles for UAV manufacturers in the selection of equipment in multi-task scenarios. This article combines work experience and tries to popularize the analysis of the main parameters of the pod. solve this problem.

1. Functional requirements for common optoelectronic pods for small and medium-sized UAVs

The photoelectric pod of the unmanned aerial vehicle system is a navigation control technology application product based on inertial navigation technology, which can effectively isolate the angular motion interference caused by the movement of the carrier to the photoelectric sensor, and can realize the identification, tracking and locking functions of the mission target. The most essential function is to achieve long-distance reconnaissance and high-quality imaging. The selection of different pod parameters and the highest functional requirements are the operating distance, which is the most core requirement of the pod. All structural design, equipment Combination, weight control, balance of performance indicators, etc. are all based on the satisfaction of the requirements on the action distance.

At present, the weight of the pod mounted on the small and medium UAV system is concentrated between 1 kg and 5 kg, and there are several common functional requirements for the pod: target search, target recognition, target tracking and target positioning. According to the different imaging principles, it is divided into visible light imaging and infrared thermal imaging. The tracking and positioning function can be calculated by the relative position of the target and the UAV or pod, or the pod can be realized by adding a laser rangefinder.

2. Analysis of main technical parameters of photoelectric pods commonly used in small and medium-sized UAVs

Because the pod involves many parameters, in order to facilitate the description, a typical product is now analyzed.

2.1 Main parameters of the system

Generally, manufacturers provide basic information such as pod structure, weight, and size, among which the core indicator is stability accuracy.

Due to the special working environment of the pod, it is necessary to continuously and effectively isolate the movement interference caused by the movement of the UAV platform to the photoelectric sensor, which will be affected by vibration, attitude change, wind resistance torque, etc. For stable and clear imaging, the pod must ensure that the boresight is continuously stable in the inertial space, that is, the improvement of the stability accuracy (the stability accuracy is generally measured in radians, where the radian is defined as the central angle corresponding to 1/360 of the circumference becomes 1 Degree angle, denoted as 1°, 1°= 60 minutes, 1 minute = 60 seconds. And the central angle of the arc equal to the length of the radius is called the angle of 1 radian, denoted as 1 (rad), and 1rad is approximately equal to 57.3°). Stability accuracy, maximum angular velocity and maximum angular acceleration can be understood as the smooth level of pod operation and the speed of response.

Tracking accuracy is another core indicator of the pod. It is the ability to track a fixed or moving target under certain disturbance conditions and keep it in the center of the field of view, which is directly related to indicators such as illumination accuracy and target positioning accuracy. However, the tracking accuracy is a comprehensive index. It is not only related to the control accuracy of the servo system, but also may be related to the tracking effect, light intensity and visibility of the image tracker. This index is based on a strong strength. Rarely mentioned.

In addition, the concept of "box" and "axis" will be involved in the pod structure. Small and medium-sized UAVs often use two-axis or three-axis pods. Because the pods are generally required to be compact in structure, light in weight, and require good environmental adaptability, the most commonly used structure is "two-axis and two-frame", three-axis The pod is in addition to the azimuth and pitch axes of the two-axis pod, and the roll axis is added. Which one is better, two-axis or three-axis? The three axes increase the roll direction, and when the UAV turns or flies over the target with an over-angle flight, it will also play a role in avoiding target loss. However, one more structure has one more hidden problem, and more structural weights need to be considered comprehensively.

In addition, every student majoring in aircraft design is committed to reducing the weight of the aircraft, so the pod sub-system also has the typical characteristics of system integration. The components of each pod manufacturer are purchased from shelf products, and the level of integration capability is the most direct. It is reflected in the weight of the system. Therefore, when comparing pod products, you will find that many indicators are similar or even the same, but the weight and size are definitely different, which to a certain extent also reflects the different design concepts and integration capabilities of each company. However, the loading pods for small and medium-sized UAVs are generally of low quality, and manufacturers can refer to their "big ball" design and integration capabilities when selecting them.

2.2 Imaging parameters

Imaging parameters are the performance indicators recommended by all pods, generally including visible light and infrared thermal imaging indicators.

2.2.1 Visible light imaging

Visible light imaging relies on the physical imaging performance of reflected light and is limited by the number and intensity of reflected light. It mainly focuses on major indicators such as element/resolution, focal length, field of view, and zoom ratio.

Image element/resolution: Pixels are made up of small squares in an image. These small squares have a definite position and assigned color value. The color and position of the small squares determine how the image will appear. A pixel can be thought of as an indivisible unit or element in the entire image. Usually, "resolution" is expressed as the number of pixels in each direction, such as 640X480, etc. The resolution is directly related to the pixels of the image. A picture with a resolution of 640 x 480 has a resolution of 307,200 pixels, which is what we often call 300,000 pixels.

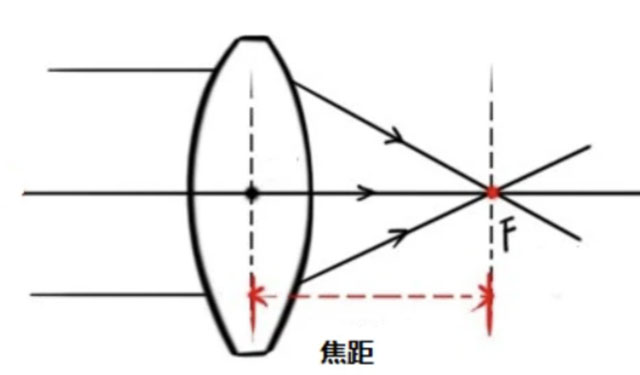

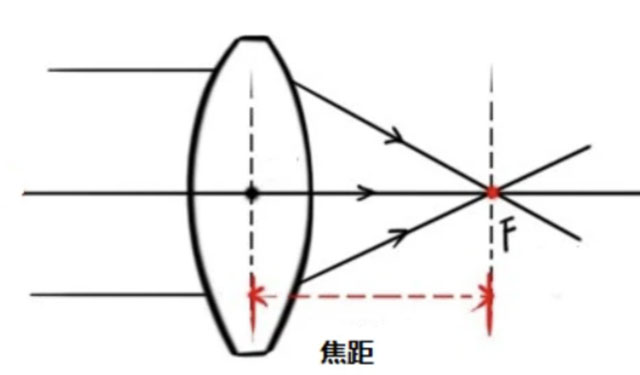

The focal length refers to the distance from the principal point on the image side of the optical system to the principal focal point. Assuming that the same subject is photographed at the same distance, the longer the focal length of the lens, the greater the magnification of the image formed by the subject on the film or image sensor.

The field of view represents the maximum range that can be observed, usually expressed in angle. The size of the field of view determines the field of view of the optical instrument. The larger the field of view, the greater the field of view. In layman's terms, if the target object exceeds this angle, it will not be included in the lens. The relationship between the field of view and the focal length: In general, the larger the field of view, the shorter the focal length.

Zoom ratio (Zoom Ration), also known as optical zoom ratio: refers to the ratio of the shortest focus to the longest focus of the zoom lens. Reflects the zoom level of the camera lens and the performance of the lens. It should be noted that digital zoom/digital zoom etc. is obtained by enlarging a fixed photo by means of software and compensating it through a certain algorithm, so digital zoom has no practical significance. Because optical zooming is achieved by physical means, that is, adjusting the distance between the lenses of the hardware, it only changes the distance of light transmission, and the light itself does not change, so the image quality will not change.

2.2.2 Infrared thermal imaging

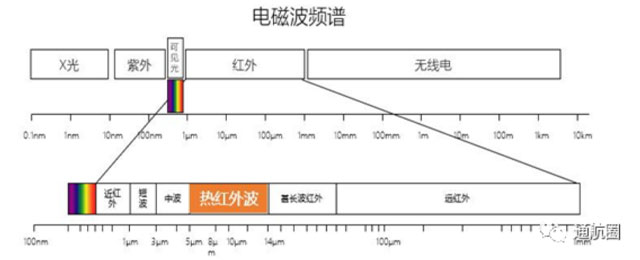

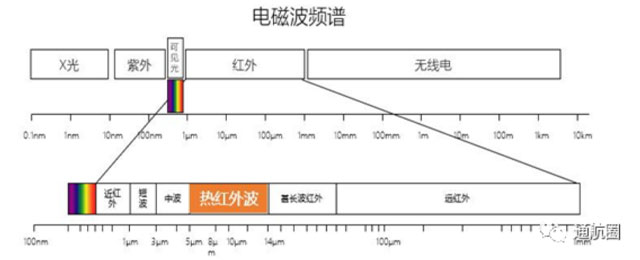

Infrared thermal imaging is because all objects in nature with a temperature higher than absolute zero (-273.15°C) radiate infrared rays all the time. Different objects have different radiation temperatures and different radiation strengths. Therefore, the target and the environment or various parts of the target The infrared radiation signature formed by the temperature difference or radiation difference between them can be used to form an image, which is ultimately used to find and identify the target.

The infrared band that can actually be detected and utilized by humans only accounts for a very small part of the entire infrared radiation band. The infrared thermal imaging of the pod mainly focuses on the main indicators such as pixel size, resolution/number of pixels, noise equivalent temperature, and minimum resolvable temperature difference.

Pixel size: In infrared imaging systems, small pixels mean an improvement in object resolution; in infrared detection systems, large pixels mean stronger energy collection capabilities.

Resolution/number of pixels: It is an important parameter to measure the pros and cons of thermal imager detectors. It indicates how many unit detection elements are on the focal plane of the detector. The higher the resolution, the clearer the imaging effect.

NETD: Noise equivalent temperature, which is a measure to characterize the temperature resolution of the infrared imaging system limited by the objective signal-to-noise ratio, that is, the thermal sensitivity, that is, the minimum temperature that the thermal imager can distinguish. The smaller the NETD, the imaging picture. The better the quality.

MRTD: The minimum distinguishable temperature difference, which comprehensively describes the ability of the infrared imaging system to distinguish the space and temperature of the target when imaging in noise.

The infrared detectors used in the pod can be divided into two types: cooled and uncooled. The cooled infrared detector has many advantages, such as faster response speed, finer picture details, higher sensitivity, longer detection distance and more stable performance. , but the performance advantage can only be realized in a low temperature environment. This makes the cooling infrared detectors have high cost, large volume and weight, and are mainly used in military and scientific research fields. The imaging detector of a non-cooled infrared thermal imager does not require low-temperature cooling. The scene change will cause the temperature of the infrared detector to change, which will be converted into an electrical signal and processed to generate an image. The device is compact, low in cost, and long in service life. , but the accuracy is relatively poor, and it is widely used in fields that do not require high imaging performance.

2.3 Other parameters

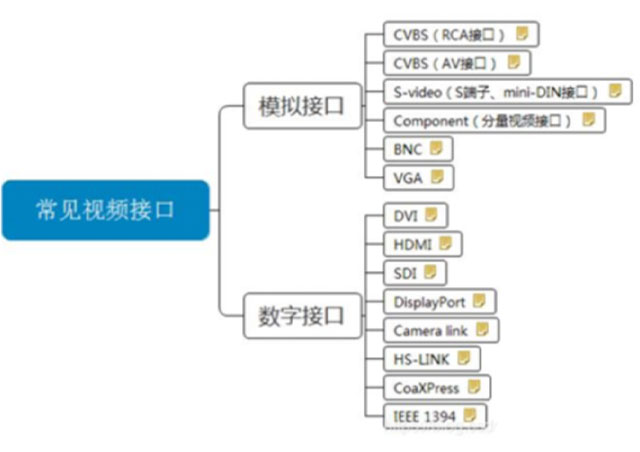

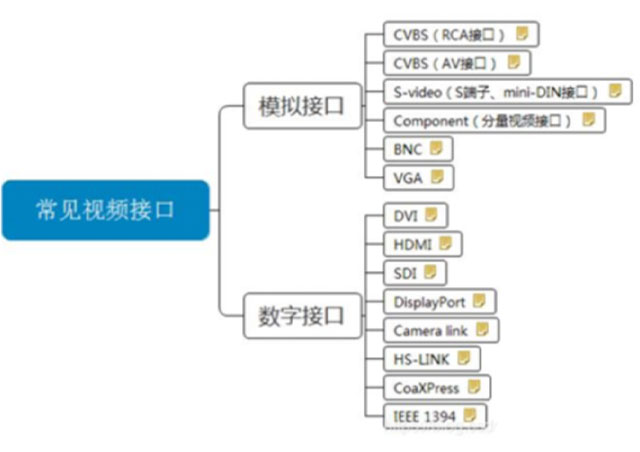

Laser rangefinder refers to an electromagnetic wave rangefinder that uses a laser as a light source, and its indicators mainly focus on ranging range and ranging accuracy. In addition, according to different project requirements, it is also necessary to pay attention to the ambient temperature and working temperature that the pod meets, the type of mechanical interface and the type of electrical interface, especially the communication interface, video output interface and communication protocol. There are many communication interfaces that can be selected in the industrial field, the common ones are as follows: serial port 232, 422, 485, Ethernet port, GPIB, USB, wireless, optical fiber, etc., among which the common communication interface of pod is 232, 422 or Ethernet network port. There are many video interfaces as follows, among which the commonly used video interfaces for pods are HD-SDI, HDMI, Ethernet, etc.

3. Other considerations in the selection of optoelectronic pods for small and medium-sized UAVs

The application scenarios of small and medium-sized UAVs are diverse. It is necessary to mount different task loads according to the task scenarios, and put forward requirements for fast loading and unloading structures for pods. With the increase of cruising speed requirements, pod manufacturers can plan buried structure design. . In some specific operating environments, the dust-proof, anti-fog, and anti-corrosion capabilities of the pod also need to be considered. Of course, factors such as product adaptability, reliability and project cost must be comprehensively considered in the process of pod selection, as well as the supply cycle and after-sales service capabilities of pod manufacturers. More is to pass the actual test first, verify the actual effect of the pod parameters provided by the manufacturer, check the quality of the received video image, and then determine the most suitable pod after meeting the needs of the project.