Engineer Manager Name: Jacky

WhatsApp/ Wechat: 0086-187 9245 6795

Email: mh_elec@126.com or jacky@mh-elec.com

Introduction:

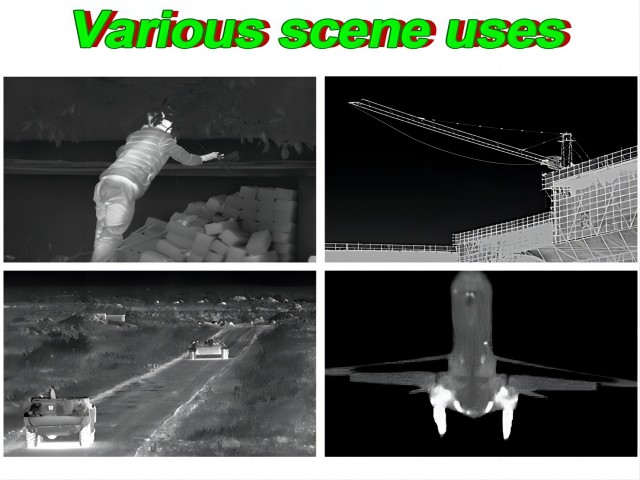

In the vast realm of infrared (IR) technology, the choice between cooled and uncooled systems is a critical decision that can significantly impact performance, cost, and application suitability. Both approaches have their unique advantages and limitations, making it essential for users to understand the nuances of cooled and uncooled IR systems before making an informed decision.

Now let MH reveal this secret for you.

Cooled:

Cooled infrared systems are equipped with a cooling mechanism, typically involving a cryogenic cooler, to maintain a low operating temperature. This cooling process enhances the sensitivity of the IR detector, allowing it to detect faint thermal radiation in the mid and long-wave infrared spectrum. The primary advantage of cooled systems is their superior image quality and sensitivity.

Advantages of Cooled Infrared Technology:

1. **Higher Sensitivity:** Cooled detectors operate at lower temperatures, increasing their sensitivity to thermal radiation. This makes them ideal for applications where detecting low-contrast targets or objects with minimal thermal signatures is crucial.

2. **Enhanced Resolution:** Cooled systems often provide higher spatial resolution, allowing for sharper and more detailed imagery. This is particularly advantageous in scenarios where precise target identification is essential.

3. **Extended Detection Range:** The increased sensitivity of cooled detectors enables longer detection ranges, making them suitable for long-range surveillance and reconnaissance applications.

Limitations of Cooled Infrared Technology:

1. **Cost:** Cooled infrared systems are generally more expensive to manufacture and maintain due to the complex cooling mechanisms involved. This cost factor can be a significant consideration for budget-constrained applications.

2. **Size and Weight:** The cooling components add bulk and weight to the system, making cooled infrared devices less practical for certain portable or space-constrained applications.

Uncooled:

Uncooled infrared systems, in contrast, operate at ambient temperatures without the need for cryogenic cooling. This technology relies on microbolometers, which are heat-sensitive materials that experience a change in resistance when exposed to infrared radiation.

Advantages of Uncooled Infrared Technology:

1. **Cost-Effectiveness:** Uncooled systems are generally more cost-effective to produce and maintain, making them an attractive option for applications with budget constraints.

2. **Compact and Lightweight:** The absence of cooling components makes uncooled systems more compact and lightweight. This characteristic is particularly advantageous for portable devices, drones, and other applications where size and weight are critical factors.

3. **Lower Power Consumption:** Uncooled systems typically consume less power, contributing to longer operational times and increased efficiency, especially in battery-powered devices.

Limitations of Uncooled Infrared Technology:

1. **Lower Sensitivity:** Uncooled detectors have lower sensitivity compared to their cooled counterparts. This can affect their performance in scenarios where high sensitivity is paramount.

2. **Limited Detection Range:** The reduced sensitivity of uncooled systems may result in shorter detection ranges, limiting their effectiveness in long-range applications.

Conclusion:

In the dynamic field of infrared technology, the choice between cooled and uncooled systems hinges on the specific requirements of the intended application. Cooled systems offer unparalleled sensitivity and image quality but come at a higher cost and with added bulk. Uncooled systems, on the other hand, provide a more cost-effective and lightweight solution, sacrificing some sensitivity and range. Understanding these trade-offs is essential for users seeking to harness the power of infrared technology in diverse fields such as defense, surveillance, and industrial applications.

These choices definitely can satisfy you at MH Tech, so hurry up and contact our professional team! !

Engineer Manager Name: Jacky

WhatsApp/ Wechat: 0086-187 9245 6795

Email: mh_elec@126.com or jacky@mh-elec.com